Silicone Profiles

-

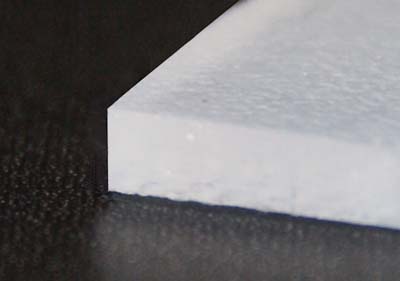

Silicone profiles are used in the welding and sealing process as an electrical isolator and as a underlay or a matching part. This is e.g. to avoid an electrical shortcut between the bar body and the heatsealing band or to balance height differences. These height differences can be caused by multiple film layers (e.g. gussets) or mechanical tolerances of the machine.

Silicone is temperature resistance up to 230°C and can temporarily withstand higher temperatures. When used as a underlay or matching layer different thicknesses and hardnesses are used for getting an optimized sealing process. Silicones can also be offered in several varieties and as well in a self-adhesive version.

arobatec provides:

Silicone in sheets/plates (for your own assembly)

Silicone in sheets/plates (for your own assembly)- Rolls, made up to your requirements

- Customized profiles (e.g. T-profile, with groove, etc.)

- Contoured shapes depending on the sealing process

- Optional: Self-adhesive as an assembly assistance and fixing

- Optional: Different colours according RAL

Silicone-Hard-Glass-Woven

-

If a harder underlayer or matching layer is needed for the sealing process a classical silicone profile can not longer be used. Then usually a silicone laminated hard glass woven is used. This is suitable for permanent temperatures of about 180 °C and is available in a self-adhesive version too.

A silicone hard glas woven is universally usable if a hard material is needed.

arobatec provides:

- Silicone hard glass woven in sheets/plates (for your own assembly)

- Stripes, made up to your requirements

- Contoured shapes according your sealing/welding tools

- Optional: Self-adhesive as an assembly assistance and fixing

If a hard material is required at higher operating temperatures, no problem ..... our heat-resistent material is specified for more than 500°C.

Heat Resistant Materials

-

Technical materials can be specified depending on the requirements of the applications. Temperature resistances with more than 1000°C are realizable. In the packaging process materials with a resistance up to 500°C are used, beside the electrical insulation a chemical resistivity might be available.

arobatec provides:

- High temperature resistant materials in sheets/plates (for your own assembly)

- Stripes, made up to your requirements

- Contoured shapes according your sealing/welding tools

- Optional: Self-adhesive as an assembly assistance and fixing (for materials up to 350°C)